Week 3 - Prototype time

Going into class I had come up with an idea for the curcious cube project, and I spent the week prototyping a circuit and mechanism to make sure the idea was possible.

The goal

For the project, I want to create a cube that responded to a person's proximity. Each face of the cube would be made of a series of vertical panels that rotated 90º. Inside the cube would be a speaker whose sound would change based on how physically open the cube is. The goal is to experiment with materiality of sound and the experience a person can have modifying it.

Since the project, which I'm considering a 'sound sculpture', is complex for the midterm I will only focus on moving a single face of the cube. Each process of the sculpture will be iterative and as each piece comes together it will inform the next. The mechanical mechanism for the face panels will be the most difficult so I started the week prototyping how it could work.

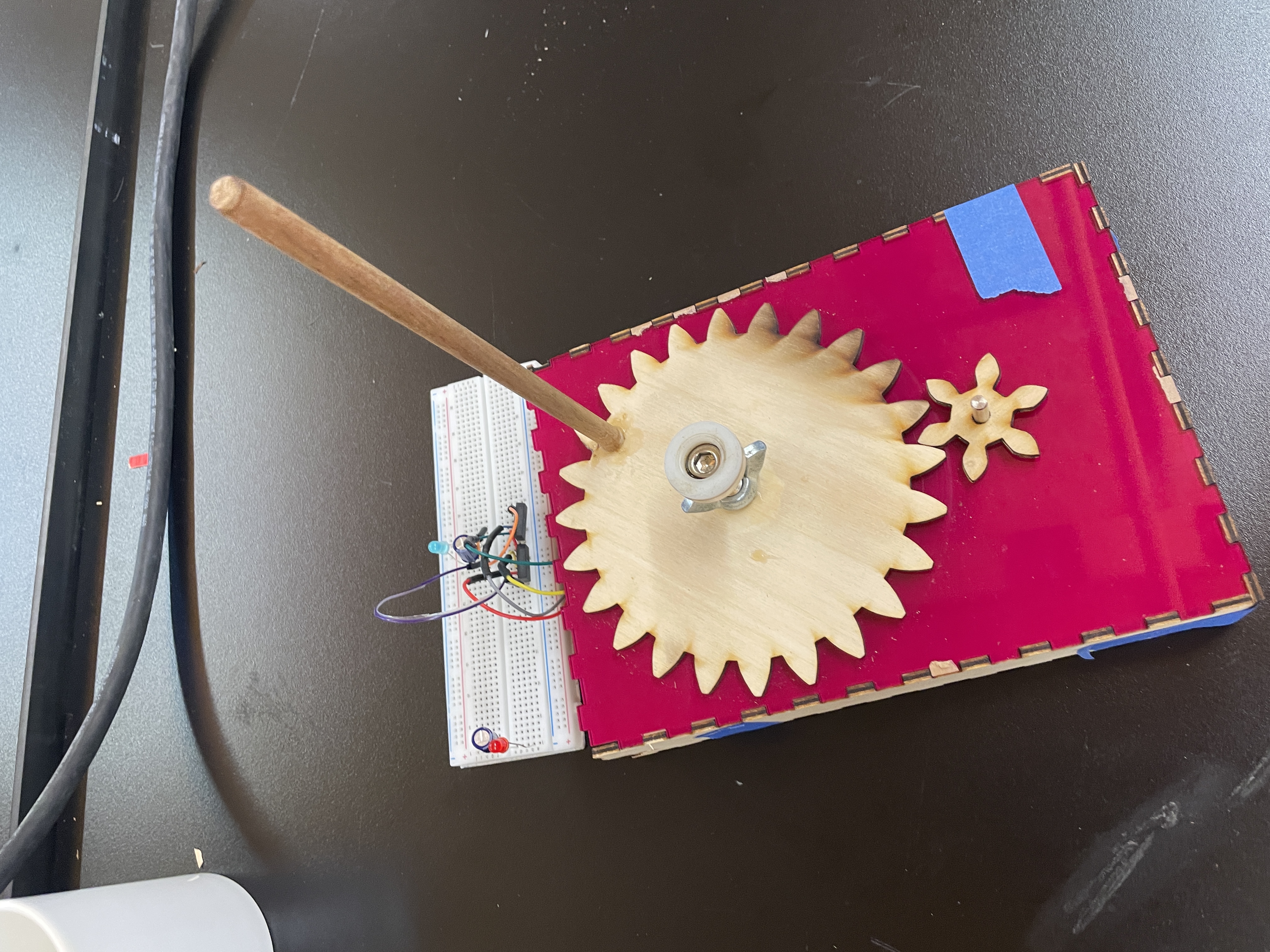

Luckily, in my Energy course we are also working on a project to convert kinetic energy into electrical energy, and for that project I am also working with mechanical motion (just in a different way). In Energy I need a large gear to conert more torque to move a smaller gear faster. Meanwhile for the cube I will need gears that are the same size to transfer an equal rotaitonal movement.

Figure 1. Simple gear prototype for Energy

Figure 1. Simple gear prototype for Energy

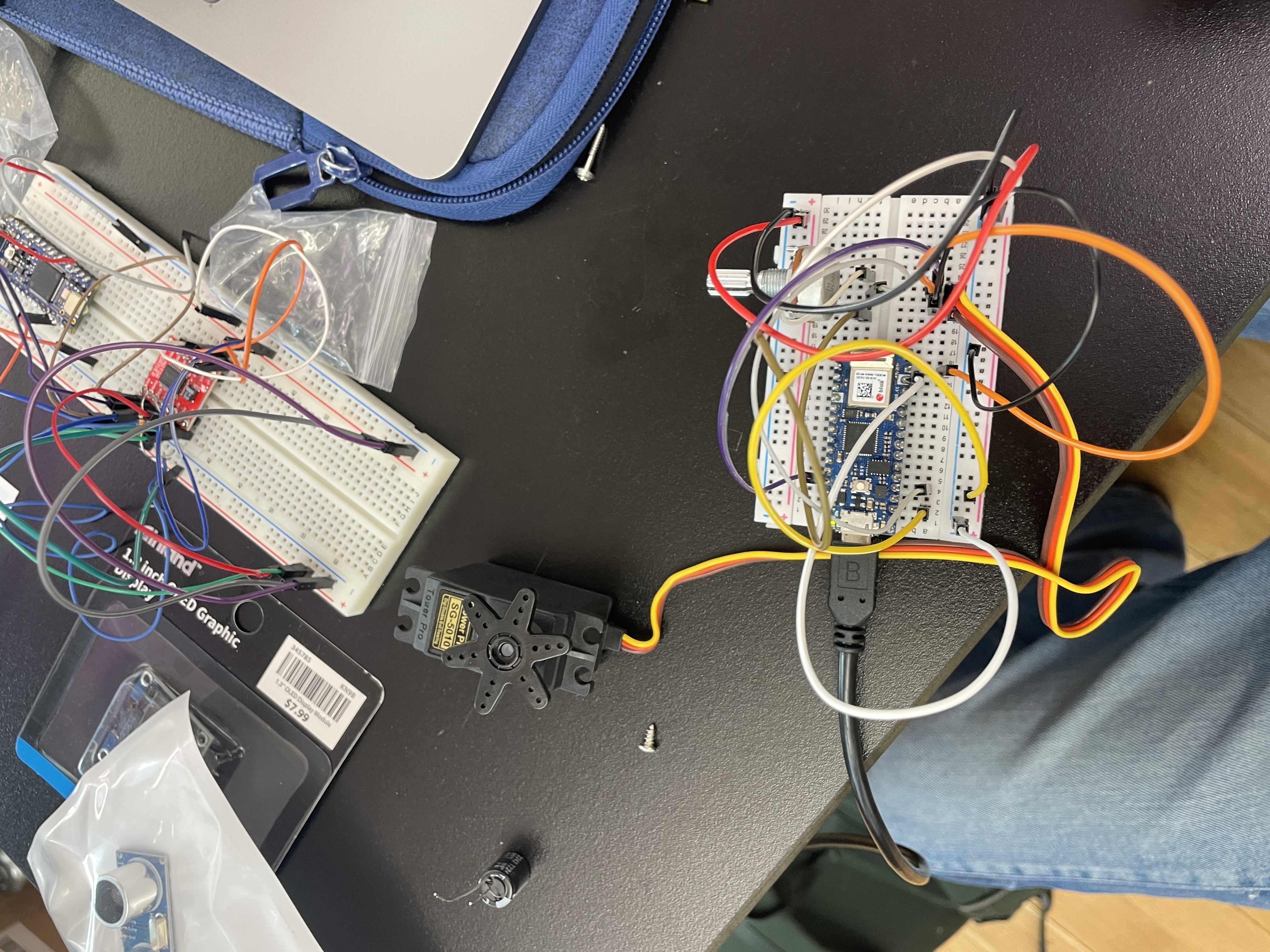

Focusing on the the cube and each panel, as a person approaches the cube a motor or servo would need to rotate 90º. I believe a servo would work best since it has more control over the position of the gear and it already works in angles. First, looking back into my pcomp labs I set up a servo to be controlled by a potentiometer.

Figure 2. Circuit to control a servo

Figure 2. Circuit to control a servo

The next part was adding in a proximity sensor. I picked up an ultrasonic sensor since it has a good sensing range and I would want a person to approach the cube from a wide angle rather than straight on. Setting up the sensor was harder than I thought. The pcomp lab seems outdated and with the code example the distance readings were really inconsistent with the sensor. I ended up finding a library called New Ping which aims to simplify ultrasonic sensor readings and it worked much better.

Another problem I ran into was that the servo and sensor combination was drawing more currant than an external power supply could provide. For now, the servo is being powered by external power, and the proximity sensor is relying on the Arduino's 5v Vin pin. However, I'd like both to be powered by the power supply eventually.

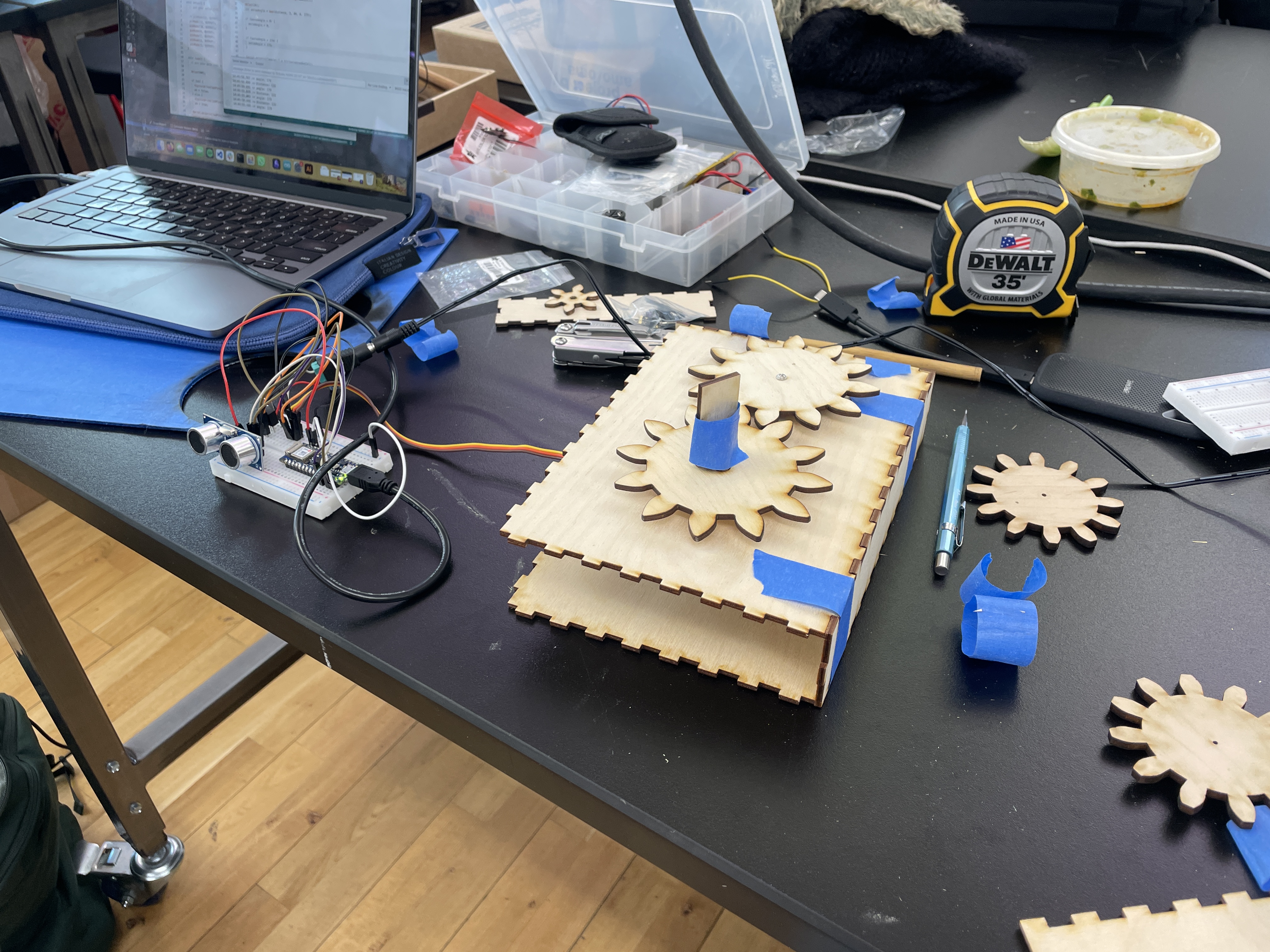

With the circuit made, I pivoted to creating a prototype mechanism to test how the servo could rotate a gear. Using scrap material by the laster cutters I found enough material to make a box and two gears. The box's height was fit to the servo so the gear could be as close to the ground as possible. Another gear was mounted to a dowel which was cut to the same height as the servo so both gears could be aligned. Since I used scrap wood, the plywood was slightly warped so the gear's teeth did not alsoway fit perfectly. Though I was surprised to see the system actually work.

Figure 4. Prototype circuit and mechanism

Figure 4. Prototype circuit and mechanism