Week 4 - Fabrication is a superpower

Like every week, coming up with an idea has been the hardest part of the project. Last week, I made a common item useless, so I decided the next thing I made could not be another useless item. It had to have a useless purpose. Eventually though, an idea dawned on me: An enclosure that can fit a single sheet of paper. Something simple but absurd in a fun way.

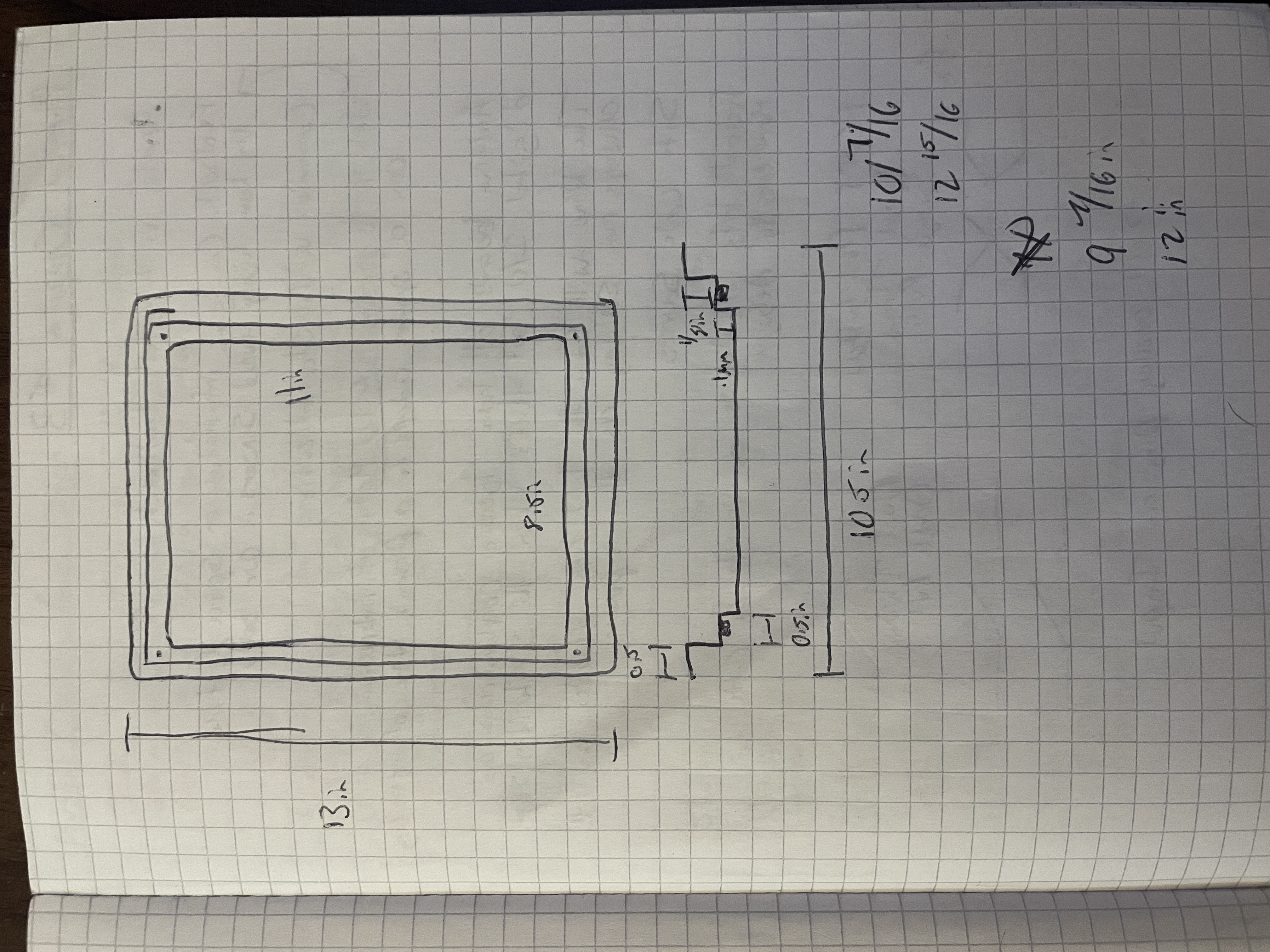

During Intro to Fab last week, I had noticed a large unclaimed piece of wood in the basement wood shop, and knew it would be a great piece of material for this week's project. Before going into actually making the object, I decided the goal would be make an enclosure using wood and acrylic to create the best possible single paper holder I could make. Next, I spent lots of time sketching and measuring before I even thought about cutting into my material. I wanted my cuts to be precise. The absuridty of this idea centered on the execution and presentation of the sheet of paper.

Sketching out enclosure measurements

Sketching out enclosure measurements

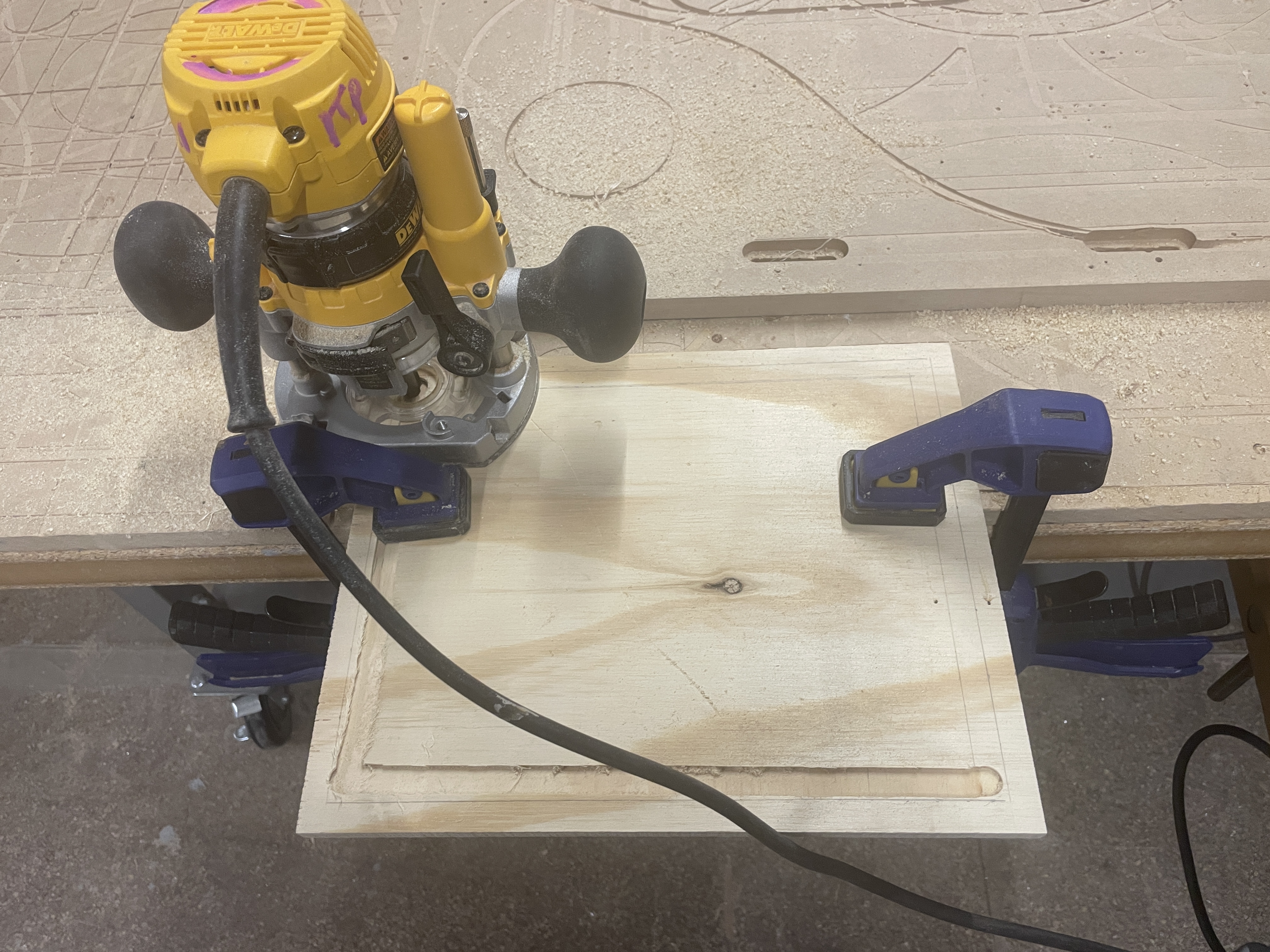

Using the router to cut out the lid space

Using the router to cut out the lid space

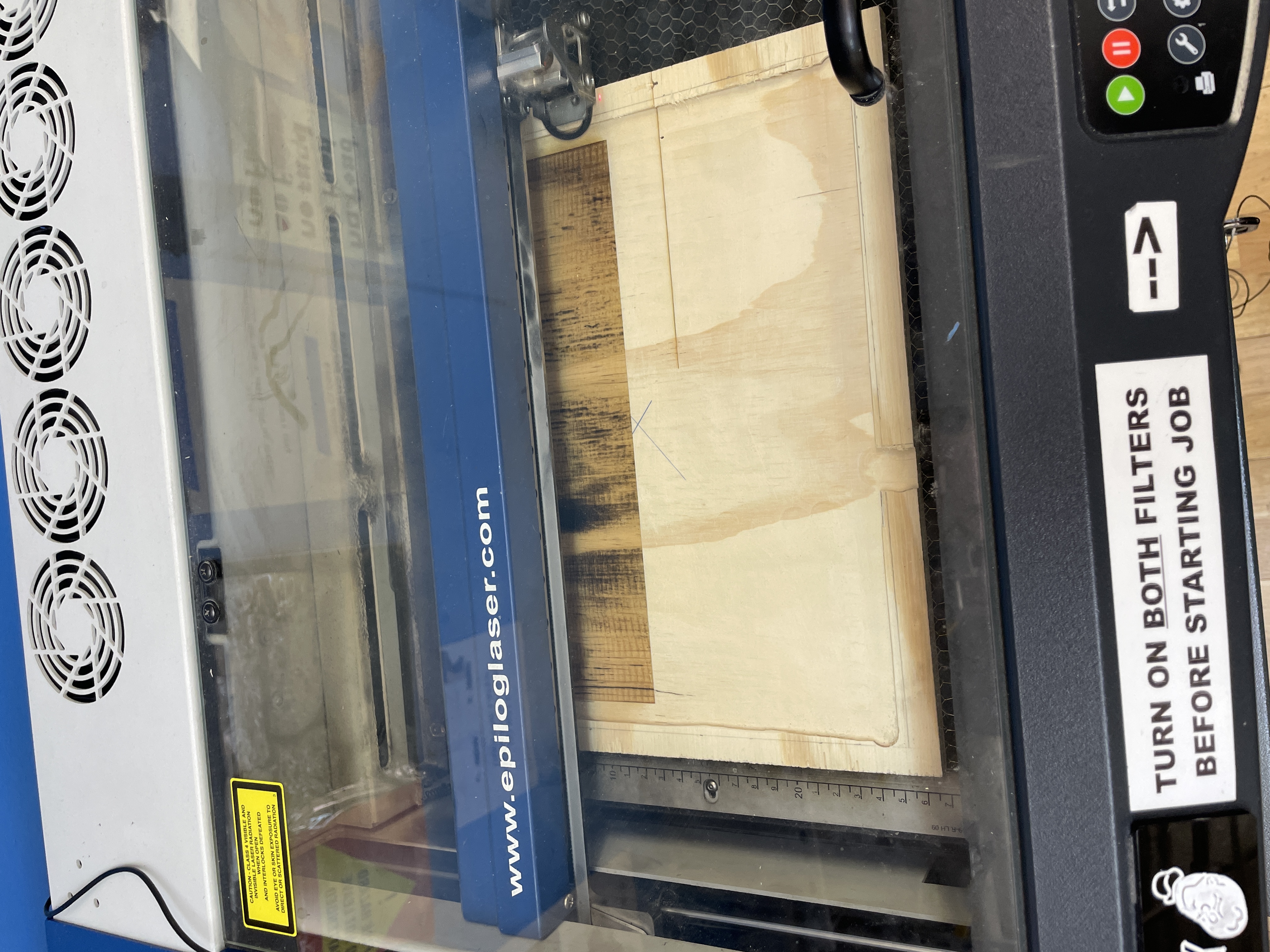

Another challenge for myself during this project was tp use the router. A tool Phil demonstrated to us, and a tool that seemed very useful for hollowing and rounding edges on a piece of wood. Ian and the shop staff were very helpful instructing how to use the router and the steps to create a guide to create an inner 1/8" depth. Perhaps out of order, the next step of my process was laser engraving the space for the sheet of paper. After some trial, error, and wrong laser cut marks, Ian helped me manually center and focus the laser cutter to text engrave an 8.5" x 11" rectangle in the center of the enclosing. At the same time, I laser cut a transparent acrylic pane to act as my lid for the enclosure.

The amount of sawdust from using a router

The amount of sawdust from using a router

Engraving the depth for the paper

Engraving the depth for the paper

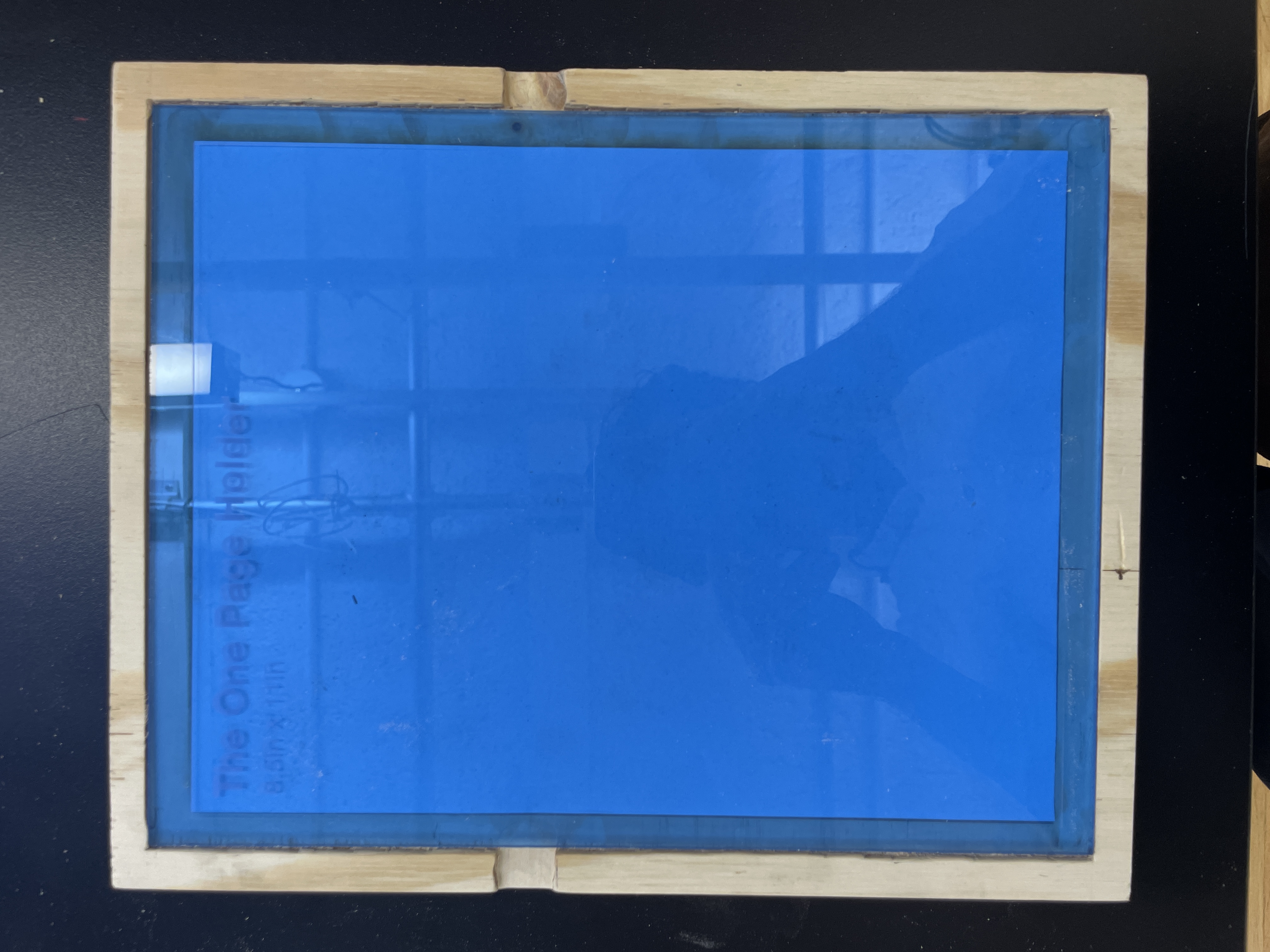

While my lid was the perfect dimensions and I had sketched out, it didn't fit into the enclosure to do imperfect edges. When I initially used the router I several of my edges weren't straight and I did not cut to the border I had marked in case I messed up my cut. So I went back the router and attempted to clean up the frame. I carefully measured and created a new guide to so I wouldn't overshoot my border. While precarious, I managed to clean up two of the four edges of the page frame. I was terrified I would mess up my wood and would have to start all over again with a back-up piece I had cut. To prevent going back to square one, I found a sharp chisel in the basement and used it to extend the edge of the frame to my measurements and create 90º corners that the router could not do. By some miracle the lid fit perfectly into the frame with less than 1/8" gap.

Cleaning the lid space edges

Cleaning the lid space edges

I could have stopped there, but I was having a lot of fun with the enclosure and I wanted the lid to have a cleaner fit and not fall out as easily. Ian had given me some tiny neodymium magnets to use and loaned me plastic drill bits to cut through my acrylic, and so I used a 5/8" bit in my acrylic and wood to pressure fit magnets together.

The finale One Page Holder enclosure

The finale One Page Holder enclosure