Week 3 - Circles are hard

Going into this week I didn't know what I wanted to make. I realized my theme was too broad and that “absurd” can have many interpretations. After deliberating over a day whether to make a useless drinking cup or a pair of square wheels, I decided (and with validation from friends) to go for the cup idea. To make the round cup shape I knew I had to use kerf bending. What I didn't know was the trial and error involved in the process. Luckily, I bought a large piece of plywood from Lowe's, so I had plenty of material to experiment with. I also found a few examples of kerf-bended circles online whose patterns I replicated in illustrator to test.

My first cut in the laser printer was to make three small kerf bending patterns to see which would bend the best, and I was incredibly nervous I would start a fire. Though Aram, one of the shop staff, walked me through the whole process. From the first cut there was no fire and I wasn't intimidated by the laser cutters as much.

Testing out kerf bending

Testing out kerf bending

The most open pattern ended up bending the best, almost to a full circle, so I continued iterating over the design and dimensions. A small join was added to the pattern to help eventually glue the two sides together. The real challenge of the project was creating a base for the cup. I had no idea how to approach the piece. Originally, I wanted the cup bottom to be and the cup itself to be a single piece and cut of material. Until I realized how difficult that would be to design.

Testing out a simple join

Testing out a simple join

Bending and glueing each object into a circle

Bending and glueing each object into a circle

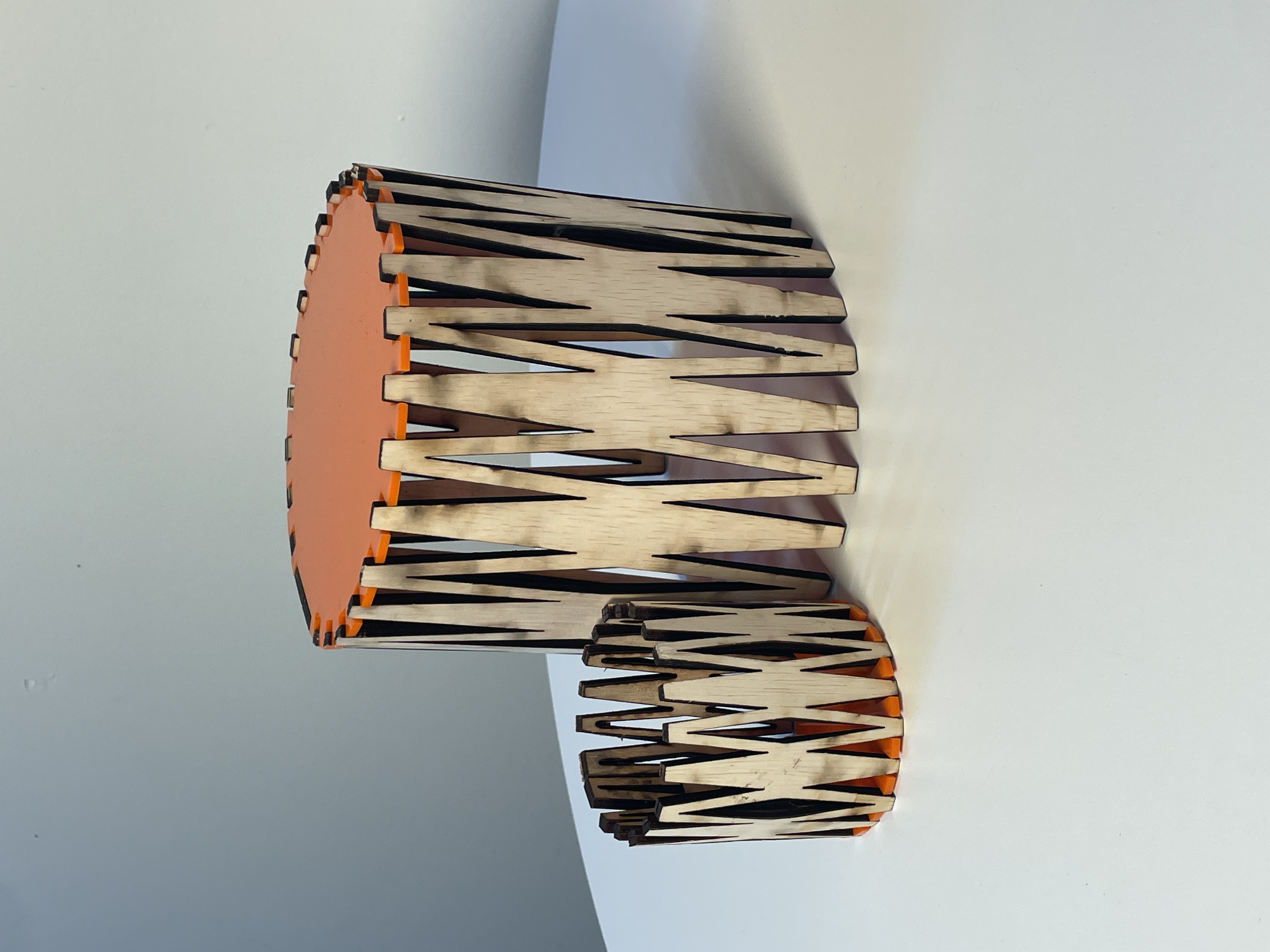

I tried using the cut out pieces from the cup walls and inverting them along each cut-out space, but the effect wasn't what I was looking for. After talking about the problem with Ian, Ray, and Justin I manually created the cup base in Illustrator. The effort involved re-cutting the cup walls to make sure all spaces had the same length, and a lot of trial and error with the size of the base teeth in order for it to fit on the object.

Almost finished cups with test cuts

Almost finished cups with test cuts

First, I forgot to account for the material width and cut a base too small for the object, then the teeth on the cup base were too small to fit on the object, and finally as the cliche states I was able to cut a piece that fit (almost too well) into the cup. Using the same strategy of counting the spaces I needed to cut and estimating the length of the join I scaled the size up to fit my large object. The large base created more areas for inconsistency, so the base fits into the cup though it is much looser.

Finished objects

Finished objects

The whole process of making the cups was frustrating, but exciting and rewarding. I'm feeling more confident in my fabrication skills and what I can make. Though now I want to push myself to make more complicated objects.

- Matt Blanco